Gear Drives

Worm Gear Speed Reducers

C-Flange Speed Reducers

Ratio Multipliers

In-Line Speed Reducers

Open Gearing

Metric Gearing

Electric Motors & Accessories

(Leeson/Lincoln)

Sub-Fractional to 350 HP

AC, DC & Wattsaver

IEC Metric Motors

Inverter Duty Motors

AC Inverters

DC Controllers

Drive and Conveyor Chains

Standard Roller Chain

Double Pitch Roller Chain

Stainless Roller Chain

Engineered Class Chain

Drag Chain

Detachable Chain

Leaf Chain

Pintle Chain

Combination Chain

Rivetless, Drop-Forged Chain

Silent Chain

Standard Metric Roller Chain

Metric Leaf Chain

Timing Chain

Sprockets

ANSI Roller Chain Sprockets

Conveyor Sprockets

Stock & Made-to-Order Sprockets

Multiple Strand Sprockets

Flame Cut Steel Sprockets

Shear Pin Sprockets

Cast Sprockets

Plastic Sprockets

Silent Chain Sprockets

Metric Sprockets

Timing Belt Sprockets

Conveyor Belting

Steel Hinge Belting

Flat Wire Belting

Chain Driven Mesh Belting

Wire Mesh Belting

Flat Belting – PVC, Leather, Rubber

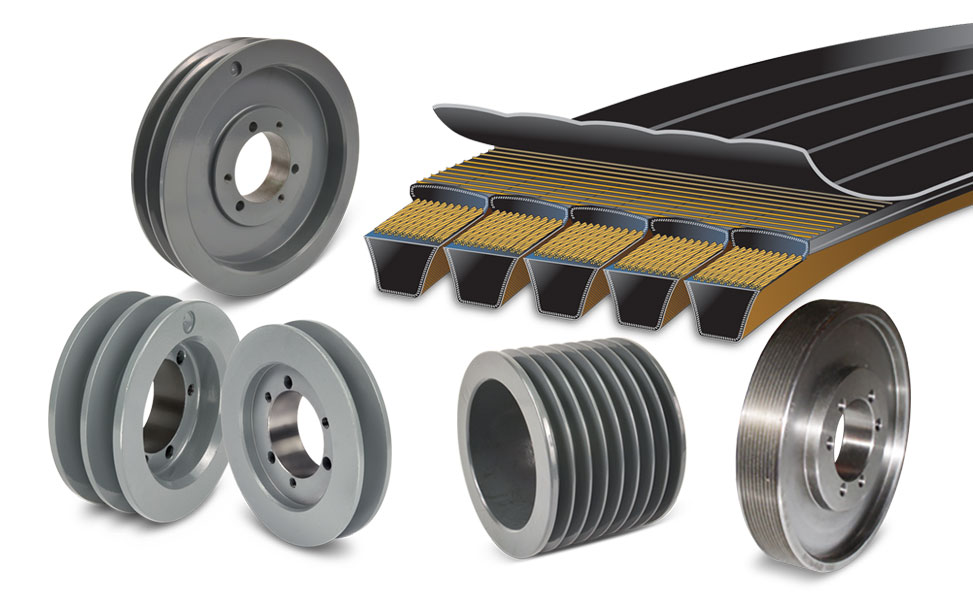

Drive Belting

FHP Belting – 3L, 4L, 5L

V-Belts - A, B, C, D

Cog Series V-Belts - AX, BX …

Kevlar Corded V-Belts

Poly V-Belts

Variable Speed Belts

Narrow V-Belts - 3VX, 5VX, 8VX

Timing Belts – XL, L, H, XH, XXH

High Torque Drive Belts (HTD)

Other Mechanical Components

Pulleys

Bearings

Shafting

Shaft Collars

Weld-On Hubs

Tapered Bushings

Radial Ball Bearings

Mounted Bearings

Bearing Inserts

Mounted Bearings

Sheaves

Mechanical Variable Speed Drives

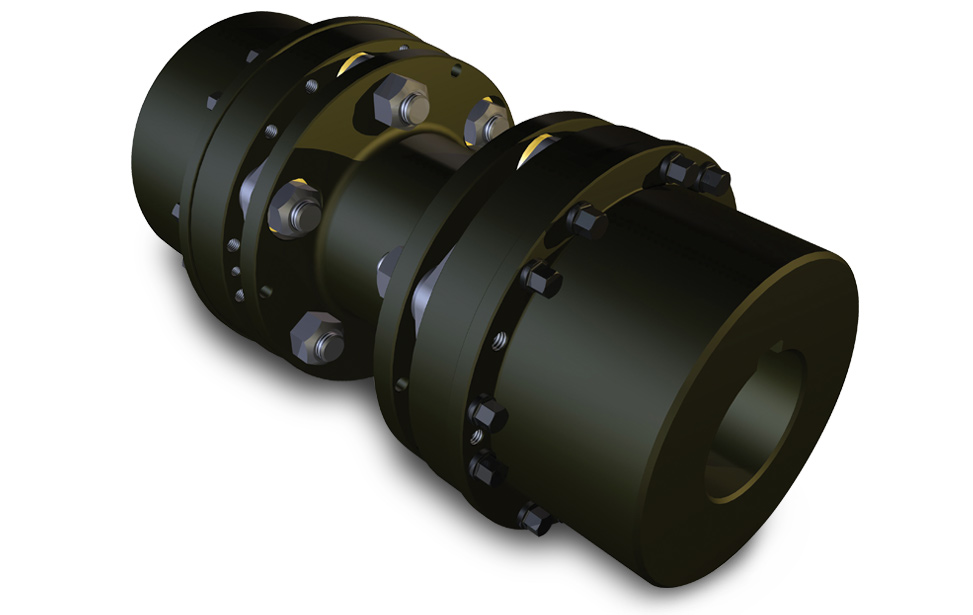

Shaft Couplings

QD & Taper Lock Bushings

Overload Safety Clutches

Torque Limiting Couplings

UST Shock Relays

Contact Us for Price & Availability!!

Light Duty FHP Sheaves and Belts

Made-to-Order Sheaves & Pulleys

Narrow Ultra-V Sheaves & V-Belts

QT Power Chain® Synchronous Belt Drives

QT Power Chain® II Carbon Synchronous Belt Drives

Synchronous & Synchronous Plus HTD Belt Drives

Var-a-Cone Variable & Adjustable Speed Sheaves

MS Variable & Adjustable Speed Sheaves

MCS Variable & Adjustable Speed Sheaves

VPS Variable & Adjustable Speed Sheaves

All-Pro Variable & Adjustable Speed Sheaves

Roto-Cone® Variable & Adjustable Speed Sheaves

Roto-Cone®-W Variable & Adjustable Speed Sheaves

Light-Duty (FHP) Adjustable Speed V-Belt Sheaves

JVS Adjustable Speed V-Belt Sheaves

Application:

Ideal for handling parts, stampings, fasteners, forgings, scrap turnings and chips - wet or dry, hot or cold. The smaller, 2-1/2” pitch units are ideally suited to complement CNC/NC lathes and machining centers. Low profile designs are available in all belt pitches to accommodate most modern production equipment. Each unit is individually engineered and manufactured to specifications of machine tool layout, material conveyed, production rate, coolant volumes, etc. A wide range of widths, lengths, inclines, and belt paths are available.

Design:

*Belt Pitches: 2-1/2”, 4”, 6”, 9".

*Belt widths from 3” to 60” (depending on pitch).

*Plain, Perforated, Dimpled conveyor belting.

*Belt cleats to suit.

*Inclines at any angle from 5 to 90 degrees.

*Heavy gauge formed conveyor channels.

*Abrasion resistant belt tracks.

*Structural Channel supports.

*Totally enclosed drive guards.

*Torque limiter overload: friction disk, shear pin,

or electronic “shock relay”.

*Flame cut steel belt sprockets.

*Heavy duty top mounted worm gearmotor

drives.

*Belt speed to suit application.

Options:

*Coolant/lubricant quench tanks to suit.

*Infeed Hoppers and discharge chutes to suit.

*Liquid tight bottom pans.

*Straight or flared side guides.

*Removable top covers, plain or reinforced.

*Chain driven wire mesh belting.

*Extra rows of side wings for belt partitioning.

*Shaft mounted gearmotor drive.

*Reinforced conveyor belting.

*Smaller units can be made portable, using

casters.

*Except for conveyor belting, units can be

manufactured from stainless steel.

*Variable speed drives.